Setting up a company in the lab: Sharing knowledge with students as a lecturer in the morning - and becoming a company boss after the lunch break. Three graduates from RWU Ravensburg-Weingarten University slip into both roles every day.

3D printing has long since revolutionized the planning, design and production of components in mechanical engineering. Three RWU alumni have dedicated themselves to this discipline and founded a company. Through their innovative strength, they are taking this production method to the next level.

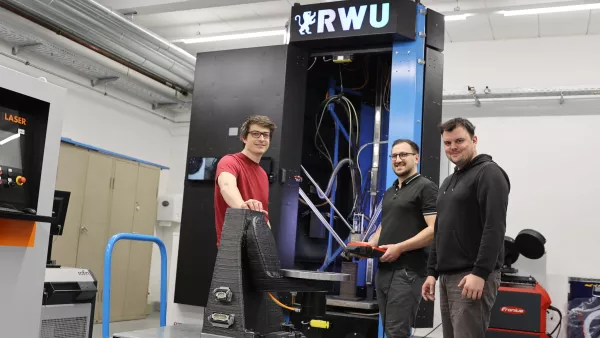

What once had to be elaborately manufactured as a special cast component can now be produced economically and in relatively little time despite small quantities. 3D printing makes it possible. Jonas Leible, Lukas Eichhorn and Christoph Dietenberger - all former mechanical engineering students at RWU - have developed and built such a metal 3D printer themselves in the additive manufacturing laboratory.

Distinctive advantages

At the beginning of the year, the triumvirate founded the company "WIRED3D". The core idea: through the ideal interaction of design, software and production, customers achieve significant advantages in the procurement of machine components compared to conventional manufacturing methods. In addition to the actual production of the components, another of the young company's services is to further develop the design of existing components. At the end of this development is a 3D model, which is then modeled by the machine layer by layer in the form of molten wire. The starting material for this is a solid wire electrode, which in turn inspired the young entrepreneurs to name their company: Wired.

Customers trust in product quality

Production is reliable and fast. In addition, the material properties and service life are decisive factors on the market. This is precisely where the three founders benefit from their work in teaching and research at RWU. "We are noticing that customers are increasingly trusting the new production process," reports Jonas Leible, who is primarily responsible for the final print in the team. "We back this up with regular material tests of the manufactured parts."

The additive manufacturing process makes it possible to combine materials in such a way that a perfect arrangement between hardness and formability is achieved. "We know that there is a high demand in the stone processing industry, for example, for tools whose functional surface is hard, but which have a high degree of formability as a component overall," reports Lukas Eichhorn. This increases the service life of the tools and reduces set-up times.

Support for RWU start-ups

The young company receives support from the "EXIST" funding program of the Federal Ministry for Economic Affairs and Climate Protection, which supports students, graduates and scientists in particular with technology-oriented and knowledge-based start-ups.

The university also provides start-up entrepreneurs with methodological and advisory support. "Specifically, we help them, for example, to validate market readiness, establish sales channels, prepare for pitches or secure follow-up financing after EXIST," explains start-up advisor Dr. Henning Wirth, who can be contacted by all RWU students interested in founding a company.

Driving technology forward

Even after the funding ends, Leible, Eichhorn and Dietenberger want to push ahead with the individual production of metal components. And, of course, WIRED3D should work in an economically sustainable way. One key to this is holistic customer advice. In future, the three engineers want to involve customers in the engineering process as early as the product development stage. Dietenberger promises: "With us, customers can help shape the entire process."

To the start-up support at RWU

RWU Start-up Days

On June 20 and 21, the RWU Ravensburg-Weingarten University of Applied Sciences will host the Start-up Days. This two-day workshop event is aimed at anyone who would like to develop their creative side in order to develop start-up ideas. More information about the Start-up Days here.